Scaling Success: How Gaia Herbs Thrives in Peak Times with Caja Robotics

Scaling Success: How Gaia Herbs Thrives in Peak Times with Caja Robotics

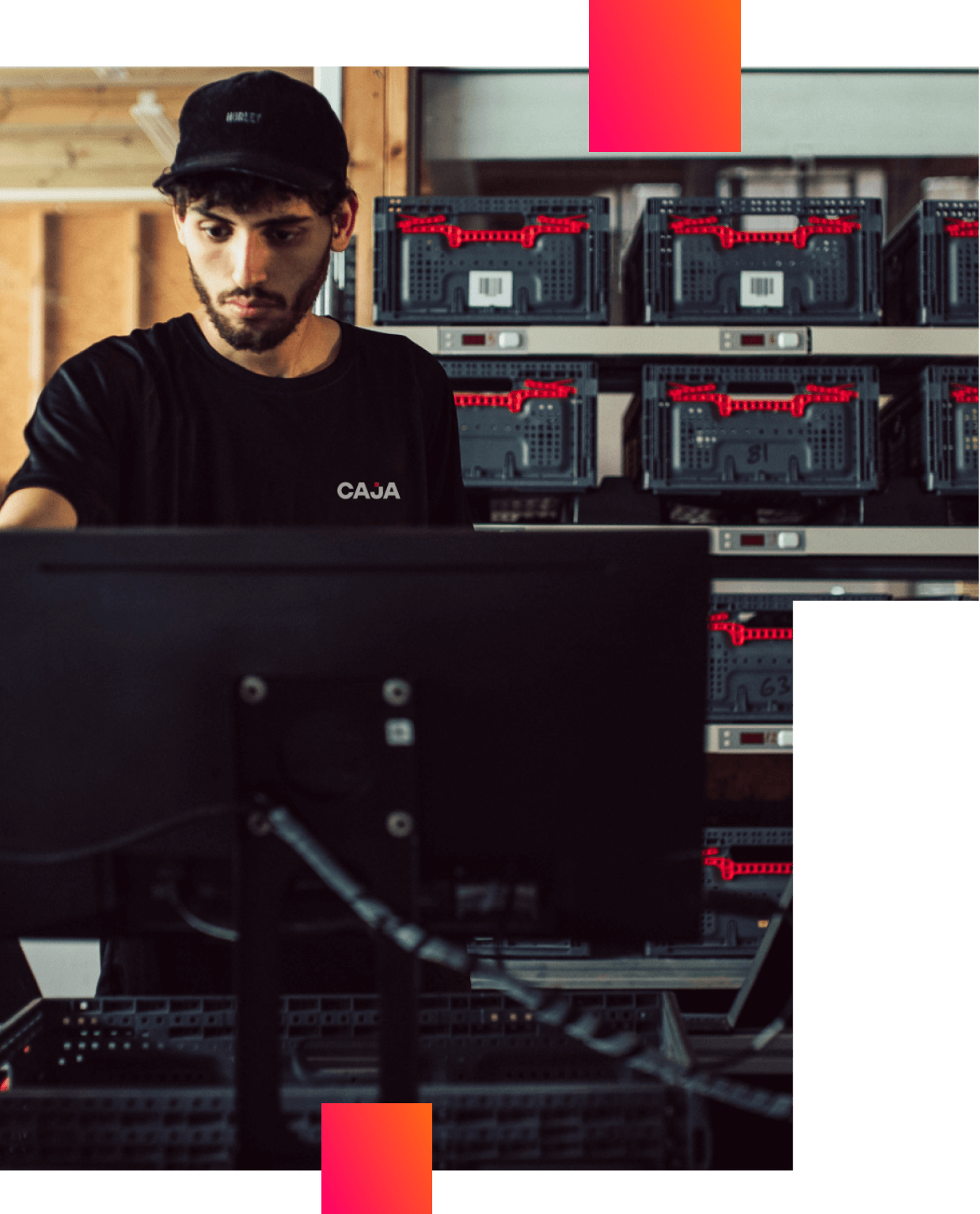

Gaia Herbs is a leading herbal supplements supplier and manufacturer based in North Carolina. When seeking to streamline fulfillment operations and meet increased demand, Gaia Herbs turned to Caja Robotics to automate its warehouse.

We recently spoke to Jarryd Player, Supply Chain Director at Gaia Herbs. He shared insights into how Caja’s solution has enhanced Gaia Herbs’ efficiency and scalability while maintaining their commitment to quality and customer satisfaction. By integrating Caja’s innovative solutions, Gaia Herbs addressed operational challenges and achieved remarkable growth.

The Shift to Automation

Gaia Herbs made the move towards warehouse automation to meet its objective of providing faster delivery, thereby enhancing customer satisfaction. As Gaia Herbs’ order volume steadily increased, the amount of manpower required to meet rising demand was becoming unsustainable. Embracing automation allowed Gaia Herbs to efficiently process orders, while keeping operational costs under control.

Partnering with Caja Robotics

When deciding on an automation solution, Gaia Herbs chose to work with Caja Robotics for several reasons. Caja’s implementation time played a big factor in the decision. The entire automation process took less than six months from decision to full operation. Caja’s highly flexible solutions allowed Gaia Herbs to address its throughput challenges in an intuitive, ergonomic manner.

Caja’s solutions’ ease of adoption allowed Gaia Herbs to quickly meet rising demand. Caja offered Gaia Herbs the scalability they needed to seamlessly expand their operations as needed. This proved particularly important during seasonal peak periods, where sudden spikes in orders had previously overwhelmed the company’s traditional manpower-based system.

Peak Time Success

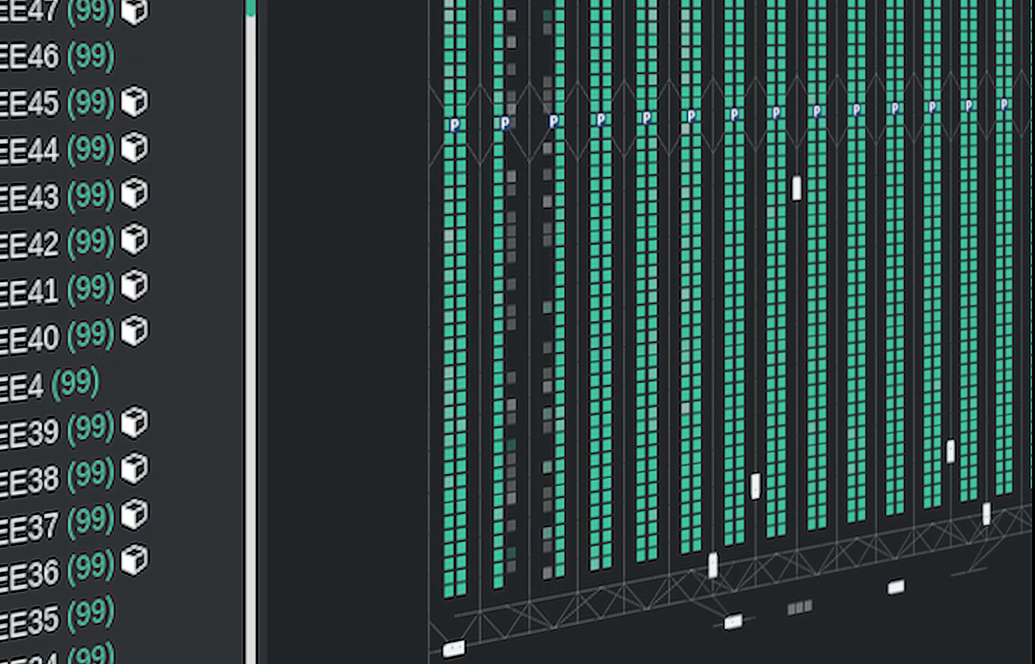

One of the key advantages Gaia Herbs gained by automating with Caja is the ability to navigate peak periods seamlessly. Caja’s technology improves workflows, letting Gaia Herbs prioritize and batch tasks, which reduces the need for unnecessary movement in the warehouse.

Caja’s system gave Gaia Herbs the tools to achieve 100% on-time delivery for six consecutive months. Gaia Herbs experienced the full impact of this over Black Friday. Previously, it took Gaia Herbs three weeks to fulfill the steep number of customer orders during this period. “With Caja, we were able to handle the demands of Black Friday in just five days, a feat that previously took us three weeks to accomplish,” explained Jarryd. “Not only did we meet the increased demand, we also achieved a threefold increase in direct-to-consumer sales.”

“With Caja, we were able to handle the demands of Black Friday in just five days, a feat that previously took us three weeks to accomplish.

Not only did we meet the increased demand, we also achieved a threefold increase in direct-to-consumer sales.”“– Jarryd Player,

Supply Chain Director at Gaia Herbs

Integrating Caja’s automated storage bins and real-time inventory management system gave Gaia Herbs a valuable buffer to maintain timely order fulfillment, even during the busiest periods. With Caja’s solutions in place, Gaia Herbs can adeptly handle demand fluctuations, ensuring timely order fulfillment without any compromise on quality.

Enhanced Efficiency

Leveraging Caja’s solutions allowed Gaia Herbs to reduce manpower by 20% without sacrificing productivity or service quality. During this period, Gaia Herbs experienced an impressive 18% growth while keeping its headcount consistently under budget.

Furthermore, automating with Caja improved Gaia Herbs’ enterprise resource planning system, ensuring resources were utilized effectively. Rather than having employees scattered all over the warehouse, they could now be designated to specific locations, such as the inbound station or picking station. This helped make Gaia Herbs’ workflow more streamlined and better organized.

Automation Reflections

Reflecting on Gaia Herbs’ experience, Jarryd emphasized the reliability of their partnership with Caja Robotics and noted that there have been no service disruptions or issues since the solution was implemented. He highlighted the importance of considering operational implications during the automation process and called out Caja’s flexibility, which makes it adaptable to various warehouse types and verticals.

In conclusion, Gaia Herbs’ partnership with Caja Robotics demonstrates the transformative power of warehouse automation. Caja’s solutions have helped Gaia Herbs seamlessly navigate periods of growth while optimizing manpower and maximizing the use of resources. As Gaia Herbs continues to scale and evolve, Caja Robotics is committed to supporting their journey towards even greater success.

One of your first considerations should be how you plan to build your automated warehouse. Greenfield refers to new builds on undisturbed land, and brownfield describes the continuation of existing projects on a site that has already been built.

One of your first considerations should be how you plan to build your automated warehouse. Greenfield refers to new builds on undisturbed land, and brownfield describes the continuation of existing projects on a site that has already been built. In order to begin automating your warehouse, you’ll need to consider the operations going on within it first. Is your warehouse omnichannel? Retail? eCommerce? 3PL?

In order to begin automating your warehouse, you’ll need to consider the operations going on within it first. Is your warehouse omnichannel? Retail? eCommerce? 3PL? Automating your warehouse allows you to improve traceability, reduce the need for manual labor, and lower operational costs, especially during the inbound process. Starting from verifying inventory when it arrives and all the way until it reaches the storage area, you’ll want a solution that can handle inventory as it arrives and check it and scan it in the most efficient way possible.

Automating your warehouse allows you to improve traceability, reduce the need for manual labor, and lower operational costs, especially during the inbound process. Starting from verifying inventory when it arrives and all the way until it reaches the storage area, you’ll want a solution that can handle inventory as it arrives and check it and scan it in the most efficient way possible. Another thing to consider before automating your warehouse is your product specifications. The volume and weight of your product may affect the types of robots and software solutions that your warehouse will need.

Another thing to consider before automating your warehouse is your product specifications. The volume and weight of your product may affect the types of robots and software solutions that your warehouse will need. Manual picking is one of the most labor intensive aspects of goods-handling. Think about it: you have to walk to the targeted rack, retrieve the product, put it in its proper tray or container, and then get walk to the next SKU’s location. All these little steps are cumbersome and time guzzling. Any improvements to this aspect of your warehouse will make a huge difference.

Manual picking is one of the most labor intensive aspects of goods-handling. Think about it: you have to walk to the targeted rack, retrieve the product, put it in its proper tray or container, and then get walk to the next SKU’s location. All these little steps are cumbersome and time guzzling. Any improvements to this aspect of your warehouse will make a huge difference. You need your warehouse automation solution to adapt and scale to your warehouse’s volumes, but also, you need to know how big your automation solution needs to be to begin with based on your SKU volume.

You need your warehouse automation solution to adapt and scale to your warehouse’s volumes, but also, you need to know how big your automation solution needs to be to begin with based on your SKU volume. Since the birth of eCommerce, reverse logistics has boomed to massive proportions. Reverse logistics refers to the movement of goods backwards through the supply chain. This encompasses everything from returns to recycling materials.

Since the birth of eCommerce, reverse logistics has boomed to massive proportions. Reverse logistics refers to the movement of goods backwards through the supply chain. This encompasses everything from returns to recycling materials. Warehouse’s will likely always need some kind of human intervention at certain stages of their operations. The current status quo is that warehouse’s rely heavily on human resources to power machines and execute tasks. This leaves a lot of room for risk and error that hinders productivity and profitability of the warehouse overall.

Warehouse’s will likely always need some kind of human intervention at certain stages of their operations. The current status quo is that warehouse’s rely heavily on human resources to power machines and execute tasks. This leaves a lot of room for risk and error that hinders productivity and profitability of the warehouse overall. In order to best gauge what kind of warehouse automation solution would best fit your needs, you need to also consider your peak to non-peak ratio. This means you need to understand the trends and peaks within your warehouse’s operational activity and choose a solution that has the ability to supply your demand.

In order to best gauge what kind of warehouse automation solution would best fit your needs, you need to also consider your peak to non-peak ratio. This means you need to understand the trends and peaks within your warehouse’s operational activity and choose a solution that has the ability to supply your demand. Implementing an automated warehouse should bring you positive results and a strong ROI within 2 years of launching it. Automation for your warehouse can be measured by the volume of the operation and how much your warehouse has been able to take on since implementing your automated processes.

Implementing an automated warehouse should bring you positive results and a strong ROI within 2 years of launching it. Automation for your warehouse can be measured by the volume of the operation and how much your warehouse has been able to take on since implementing your automated processes.