Mobile Robots

How mobile robots are transforming the warehouse industry

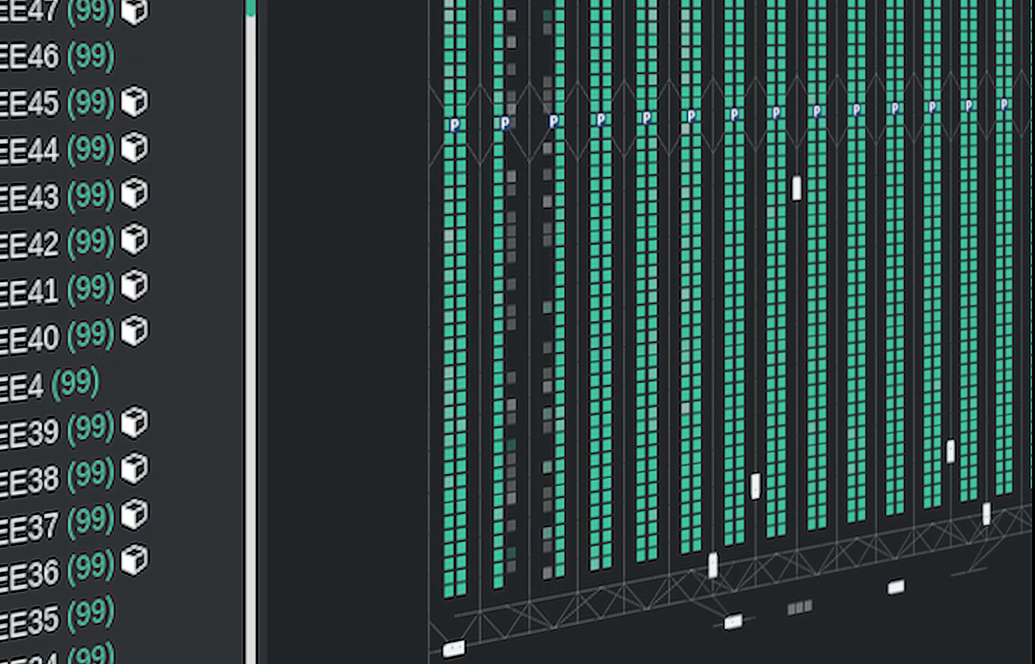

The rise of e-commerce has brought unprecedented challenges for the warehouse and logistics industry. In order to keep up with consumer demand, warehouses must find ways to become more efficient and productive. One increasingly popular solution is the use of autonomous mobile robots (AMRs).

AMRs are revolutionizing warehouse operations by automating tasks that are traditionally done by human workers, such as picking and packing orders. By doing so, AMRs can help increase productivity while also freeing up employees to perform other tasks. Additionally, AMRs can operate for longer hours than humans and do not require breaks, which further adds to their efficiency.

Despite the many benefits of using AMRs, there are also some challenges that come with them. One major challenge is ensuring that the robots can safely navigate around the warehouse without colliding into objects or people. Additionally, warehouses will need to make sure that they have enough charging stations for the robots, as they will need to be recharged regularly.

Despite these challenges, it’s clear that AMRs are here to stay and are changing the landscape of the warehouse industry. Below, we’ll take a closer look at how AMRs are being used in warehouses and what the future holds for this rapidly growing industry.

AMRs in

warehouses

As mentioned earlier, one of the major advantages of using AMRs in warehouses is their ability to automate tasks that are traditionally done by human workers.

This can help increase productivity while also freeing up employees to perform other tasks. For example, rather than having employees spend their time walking around the warehouse to find items that need to be shipped out, AMRs can be deployed to do this instead. This allows employees to focus on other tasks, such as packing orders or checking inventory. Additionally, unlike human workers, AMRs can operate for longer hours without needing breaks. This means that they can work around the clock to get orders out as quickly as possible. Additionally, because they don’t get tired, they’re less likely to make mistakes when performing their tasks.

Another advantage of using AMRs is that they can help improve safety in warehouses. This is because they can be equipped with sensors that help them avoid collisions with objects and people. Additionally, if an accident does happen, there’s less risk of serious injury since AMRs weigh significantly less than human workers.

Lastly, deploying AMRs in your warehouse can also help you save financial ressources in the long run. This is because they don’t require benefits such as healthcare or paid time off like human workers do. Additionally, you won’t need to invest in as much safety equipment since there’s less risk of accidents occurring.

Despite all these advantages, there are still some challenges associated with using AMRs in warehouses which we’ll discuss next.

Challanges of using AMRs in warehouses

As with any new technology, there are always going to be some challenges associated with its use. When it comes to using AMRs in warehouses, one of the major challenges is ensuring that they can safely navigate around the premises without colliding into objects or people. To do this effectively, warehouses will need to invest in high-quality sensors for their robots . Additionally , they’ll need to have a clear understanding of their layout so that they can map it out for the robots . If not , this could lead to disruptions in workflow and increased downtime .

Another challenge associated with using AMRS is making sure that there are enough charging stations for them . Since they will need to be recharged regularly , it’s important that there are enough stations so that they don’t have to wait too long before getting back to work . This could lead to decreased productivity and increased downtime .

Lastly , another challenge associated with using AMRS is ensuring that they are integrated seamlessly into existing warehouse operations . This includes having a clear understanding of how they will interact with other pieces of equipment , such as conveyor belts , and how they will fit into your existing workflow . If not properly planned , this could lead to disruptions and decreased efficiency . Despite these challenges , it’s clear that autonomous mobile robots are here to stay and are changing the landscape of the warehouse industry . With proper planning and execution , they can help increase productivity , safety , and efficiency in your warehouse . As e – commerce continues to grow , it’s likely that more and more warehouses will begin deploying these robots in order meet consumer demand . What does the future hold for autonomous mobile robots ? Only time will tell but one thing is for sure – these machines are here to stay.

Meet our robots

Contact us

Automate your warehouse now!