Robots

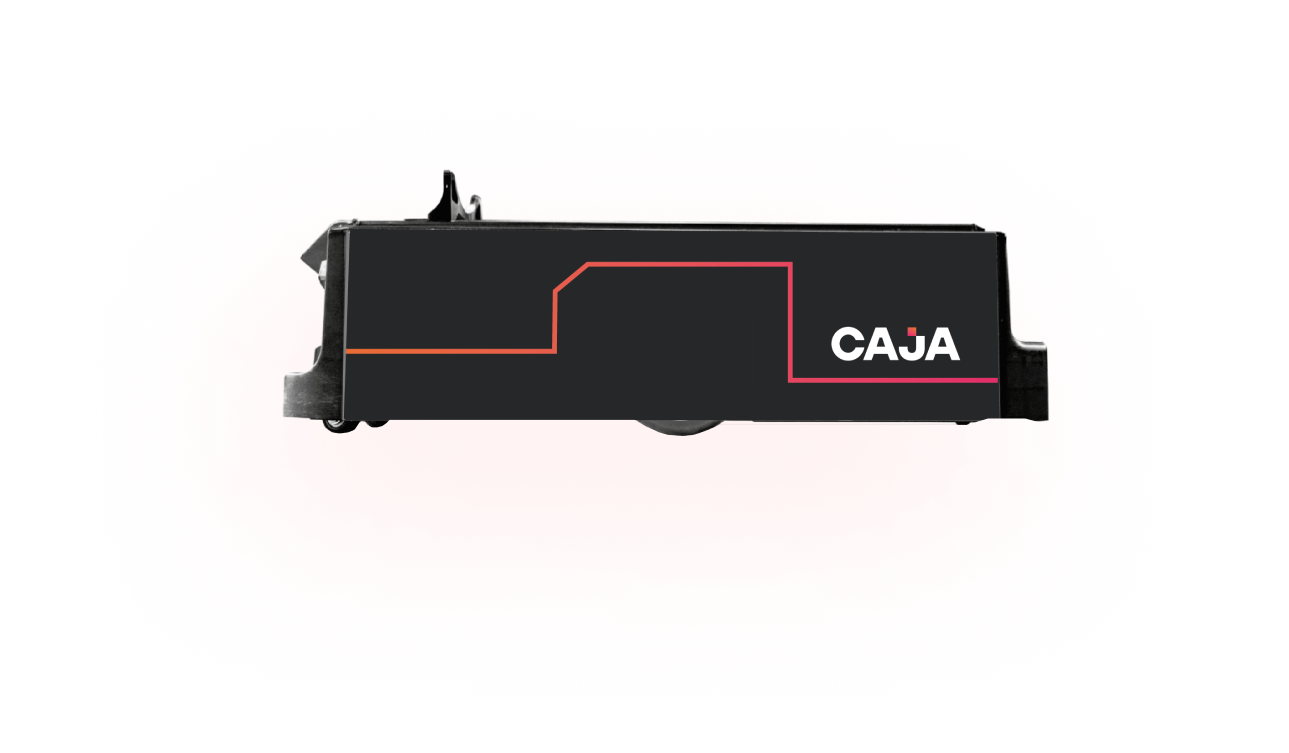

Meet Skyler™ & Sprynter™.

Technology

Advanced robotics

On the warehouse floor, the robots communicate with the back-end wirelessly, using their sensors to learn their location,

4D navigation

Our robots are controlled by cloud-based, decentralized software, running multilayered advanced algorithms.

Autonomous

For some procedures, there is no advantage for the cloud to control the robots. At these spots, the robots ‘take the wheel’

Temperature

As the world of fulfillment centers expands to many verticals, we understand there are different demands for different industries.

Advantages

Adaptability

Caja believes in a system that adapts to the warehouse infrastructure and not vice versa. Therefore, we have developed

Scalability

In the rapidly changing world of logistics, changes in volume are common, whether due to peak times or changes to the scale

Responsivity

Caja’s system continuously optimizes the warehouse and responds to sudden and unexpected challenges.

Work Process Definition

Technical Specifications

| Sprynter™ | Skyler™ | |

|---|---|---|

| Min. gripping height | 280 mm | 280 mm |

| Max. gripping height | 800 mm | 3200 mm |

| Robot footprint | 840 mm 415 mm | 1300 mm 850 mm |

| Weight | 55 kg | 350 kg |

| Max. Navigation speed | 2m s | 1.5m s |

| Max battery runtime | 8 Hrs. | 6 Hrs. |

| Daily operating time | Operating time | Operating time |

| Max Bin load | 30 kg | 30 kg |

| Min. object dimensions | 397mm x 590mm | 397mm x 590mm |

| Max. object dimensions | 403mm x 610mm | 403mm x 610mm |

News and Events

Contact us