3PL

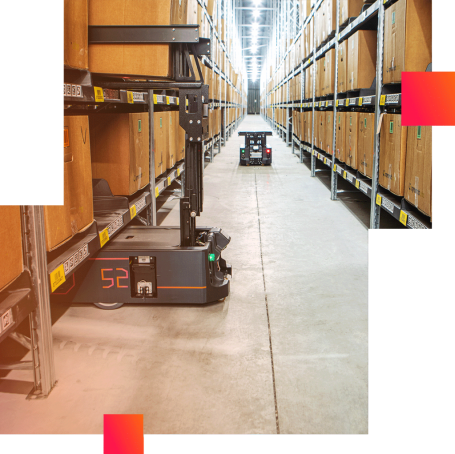

With an exponentially growing number of small and medium companies needing fast and accessible shipping to sell their goods online, comes the need for storage and logistics fulfillment centers. Handling the entire warehouse is not for everyone, financially and logistically. For that reason, 3PL (third-party logistics) fulfillment centers are sprouting like mushrooms after the rain.

3PL centers allow an easy way to keep e-Commerce customers satisfied with no need to handle the entire logistics of order fulfillment, including shipping, storage, inventory management, and return handling.

Market Characterization

Multiple companies in one warehouse

Need for flexibility

Different needs for each company facilitated

A huge number of SKUs

Efficient space utilization

The fast growth of e-commerce

Multichannel orders in the same fulfillment center

Rapidly increasing order volumes

Fast deliveries

Large volume of returns to be handled quickly and accurately

Shortage of reliable warehouse workers

Changing demand during peak times

Demand for delivery accuracy

Different size boxes

Caja’s solution

Caja Robotics warehouse automation solution uses an improved approach for handling the challenges of 3PL fulfillment centers – an adaptive, scalable, and responsive system that can handle not only today’s market needs but future changes too.

Caja’s solution is optimized for the 3PL logistics world.

Caja understands the specific challenges of 3PL fulfillment centers, which are multiplied by the number of clients facilitating the warehouse.

Our system affects everything from the multi-company inbound replenishment process to the daily tasks that demand synchronizing with pre-installed WMS (Warehouse Management Systems), as well as in the management of omni-channel orders, future order prediction algorithms, and warehouse optimization. Throughout the process, the solution is designed for optimization.

Order returns, which are usually a very complicated part of the warehouse managing process, are made fast and simple thanks to the smart algorithm and WMS synchronization, which bring item availability back online quickly.

Our two types of picking stations optimize the picking process for all companies at the fulfillment center, each with its own needs and specifications.

The e-Commerce market is tied to peak times and market changes that strongly affect the 3PL industry. since Caja robotics’ system is elastic and adaptable, an easy and fast expansion of the number of robots is possible during peak times or when fulfillment center growth is needed.

Each company hosted in a 3PL fulfillment center has its suppliers. This fact creates a challenge of handling the different size and material boxes. Caja has a solution for this dynamic range of sizes and materials. Our two types of robots designed to deal with this kind of diversity.

Caja’s solution for 3PLs is not just a picking platform, it is a full-process, A-Z solution.

News & Events

I can’t explain – in words – how excited I am to see this strategy pay off with this large Caja installation. It will not only benefit the customer but could potentially provide a solution for an entire industry segment.

Drew Eubank

Director of Customer Solutions at AHS

Contact us