4D Nav

Background

One of the most important tasks for every fulfillment center, manual or automatic, is the need to get the items from the shelves to the outbound process – and to get there fast.

In the robotic automation world, there are many solutions on the market, from robots that walk side by side with workers just to help carry the items (COBOT), to heavy automation infrastructures like shuttle systems. Each of the solutions out there aims to shorten the time spent picking and get the order ready faster.

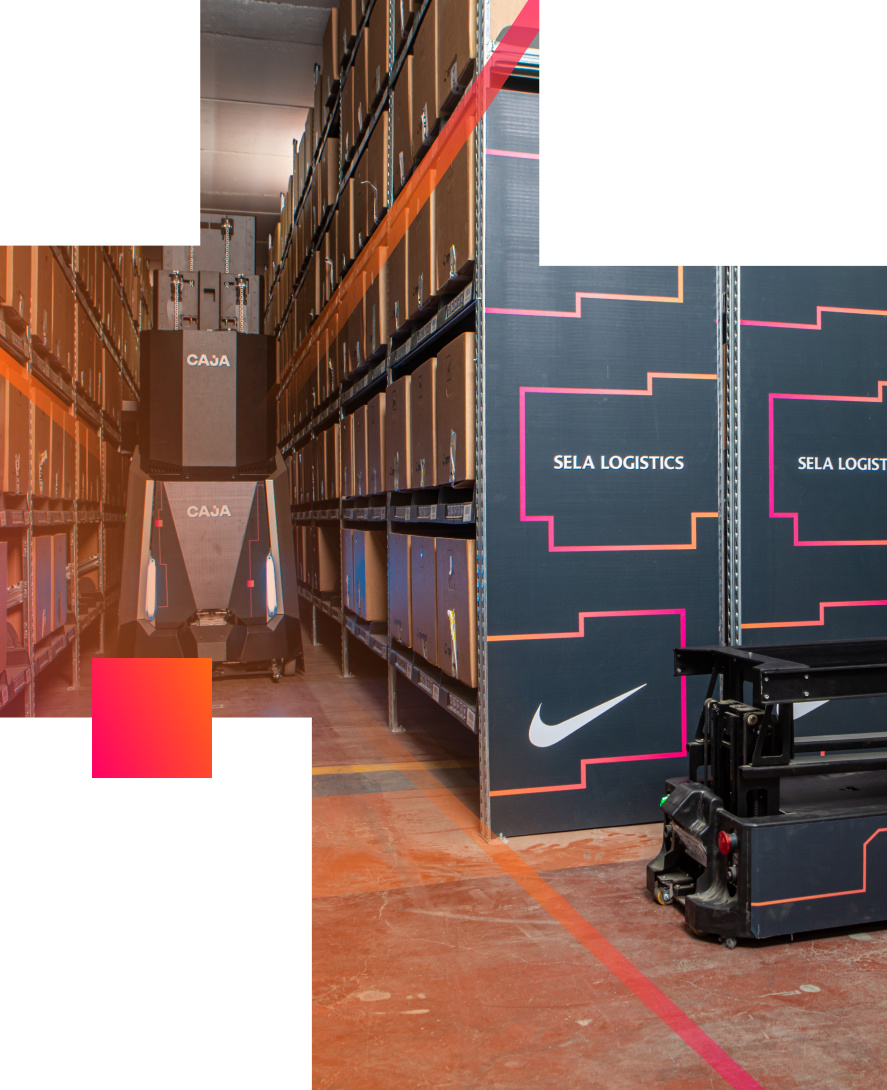

Caja Robotics’ solution aims to perform as fast as possible with minimum infrastructure changes so the logistics of the process meet the warehouse’s demands while providing great ROI.

To achieve great order delivery times without having to spend a lot of money on fixed, non-flexible construction, Caja created its state-of-the-art 4D Nav advanced algorithm, managed by our cloud. Navigating in a dynamic environment and finding routes by seeing the whole picture, and not just sections of it, is nothing less than revolutionary compared to traditional AMRS navigation.

Getting there fast in the fulfillment world is much more than getting from point A to B, especially when we consider multi-robot systems being used for replenishment, warehouse optimization, picking, consolidation, and many other processes at the same time. Caja’s solution is built to deliver maximum results in the most optimized manner.

Caja Robotics’4D nav

A Consolidation process made by Caja’s algorithm creates optimization of storage space usage, together with an option of the same bin with multi-SKU’s inside, brings the fulfillment center space usage to its max.

As the market is bound to peak times and market changes, an easy and fast expansion of a number of robots is possible during peak times or when fulfillment center growth is needed, as Caja robotics’ system is elastic and adaptable.

The apparel fulfillment centers are characterized by different sizes of boxes and even Hangers-based. Caja has a solution for this dynamic world of sizes and materials. Caja has 2 types of robots with specific abilities for each. Both works synchronically and creates a synergetic system.

Caja solution for the Apparel market is not just a picking solution, it is a full-process one, from A-Z

4D Nav advantages

Faster sterile

environment

Caja’s robot ‘playground’ is an enclosed and human-free environment, allowing for high speed during both inbound and outbound activity. When the option for unplanned obstacles, such as people, is minimized, our robots can reach much higher speeds. Just think of the difference in speed you can achieve when driving on a highway vs. driving in a pedestrian zone.

Our multi-layered algorithms handle prediction problems that are usually only handled at the research level, such as Multi-Agent Path Finding (MAPF). Caja’s 4D navigation technology brings theory to real life for fulfillment center optimization.

No

Deadlocks

Fast,

not short

Accurate

simulations

Heading

Challenges

Local problems– When there’s a pinpoint problem, such as floor damage or obstacles in the way, the 4D Nav technology runs new simulations, avoiding that specific location and choosing new routes with the fastest navigation and minimal changes to the robots‘ instructions.

Robot/Bin problems– A malfunctioning robot or damaged bin doesn’t put the entire operation on hold, as Caja Robotics’ 4D Nav can close a specific section and route all traffic around it. Once the problem is fixed, the selected area is no longer problematic and will be open for traffic again. We have a rate of 99% automatic full recovery with no human interference.

Get in touch

All Rights Reserved to CAJA 2023

All Rights Reserved to CAJA 2021.