Grocery

There is a continuously growing demand for online grocery shopping, for home delivery or click-and-collect. With higher demand for variety of food and beverages, fulfillment centers handling grocery products are becoming widespread. The key to efficiency is automating the picking process. This is the only way to meet the rising demand now that anyone can submit a grocery order from the smartphone in their pocket.

Market characterization

FEFO – First Expiration, First Out

Different size

orders

Changing demand during peak times

A variety of storage climates

Fast growth of e-commerce food orders

Multichannel orders handled in the same fulfillment center

Fast deliveries

Shortage of reliable warehouse workers

Demand for delivery accuracy

Food safety – less human intervention

Caja’s solution

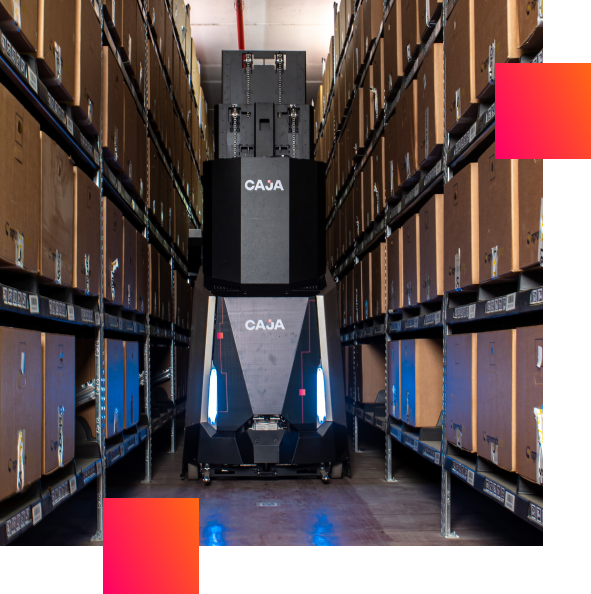

Caja Robotics’ adaptive, scalable, and responsive solution is made to futurize your grocery warehouse with ease.

Caja’s solution is optimized for grocery fulfillment center logistics.

The main concern of this industry is the freshness of delivered goods and avoiding expired products, so our system supports a FEFO feature – items close to their expiration dates are the first ones to go out for delivery – benefiting both the customers and the fulfillment center.

Another key feature the grocery industry demands is multi-climate areas to handle fresh products in addition to dry ones. Caja Robots are adapted to this need and can deliver the goods.

Caja’s solution is designed for optimization, from the lightning-fast inbound replenishment process that fits multi-sized bins and boxes to the daily tasks that demand synchronizing with pre-installed WMS (Warehouse Management System). Meanwhile, it also carefully controls omni-channel orders, future orders prediction algorithms, warehouse optimization, and orders returns, making them fast and simple using WMS synchronization, which brings item availability back online quickly.

Caja grocery goods-to-person picking process keeps delivery accuracy at peak levels, and fits your FEFO needs, sending out items close to expiration dates first.

Our two types of picking Pack-Checks- Sync and aSync optimize the picking process for both low-volume item orders and bulk orders. Our Pack-Checks can even go hybrid.

The bin consolidation process, combined with multi-SKU bins, creates optimized storage space usage and maximizes fulfillment center space usage.

Caja robotics’ system is elastic and adaptable, offering fast and easy expansion of the number of robots during peak times or fulfillment center growth. Caja’s solution for the grocery market is not just a picking platform, it is an A-Z full-process solution.

Case studies

Caja latest features on French i24News

Caja latest features on French i24News

Caja latest features on French i24News

I can’t explain – in words – how excited I am to see this strategy pay off with this large Caja installation. It will not only benefit the customer but could potentially provide a solution for an entire industry segment.

Drew Eubank

Director of Customer Solutions at AHS

Get in touch

APPLICATIONS

Fashion

Shoes

Grocery

Food and Bev

Pharma

3PL

Ecom

Industry

TECHNOLOGY

Cloud

Ai

4D Nav

Machine Learning

Advanced Robotics

Simulation

Fleet Management

Wh Optimization

SYSTEM

Robots

Picking Station

Software

COMPANY

About

News and Events

Leadership

Career

SUBSCRIBE TO OUR NEWSLETTER

Follow us

All Rights Reserved to CAJA 2021.